Your Resource Hub for Success

At Carus, we are committed to empowering your business or municipality with reliable, high-quality products and expert support. Our resource hub offers a wealth of information, including webinars, case studies, product safety summaries, and more, to ensure you have everything you need to make informed decisions. With a focus on safety, sustainability, and innovation, we strive to deliver consistent value, exceed expectations, and provide solutions tailored to your needs. Explore our resources and discover how Carus can help drive your success.

Webinars

Data Sheets

Permanganate

- AQUOX® potassium permanganate ACS reagent grade

- AQUOX® potassium permanganate pharma grade

- AQUOX® potassium permanganate free flowing grade

- AQUOX® potassium permanganate technical grade

- CAIROX® potassium permanganate ACS reagent grade

- CAIROX® potassium permanganate pharma grade

- CAIROX® potassium permanganate free flowing grade

- CAIROX® potassium permanganate technical grade (for municipal drinking water)

- CAIROX® potassium permanganate technical grade (for industrial)

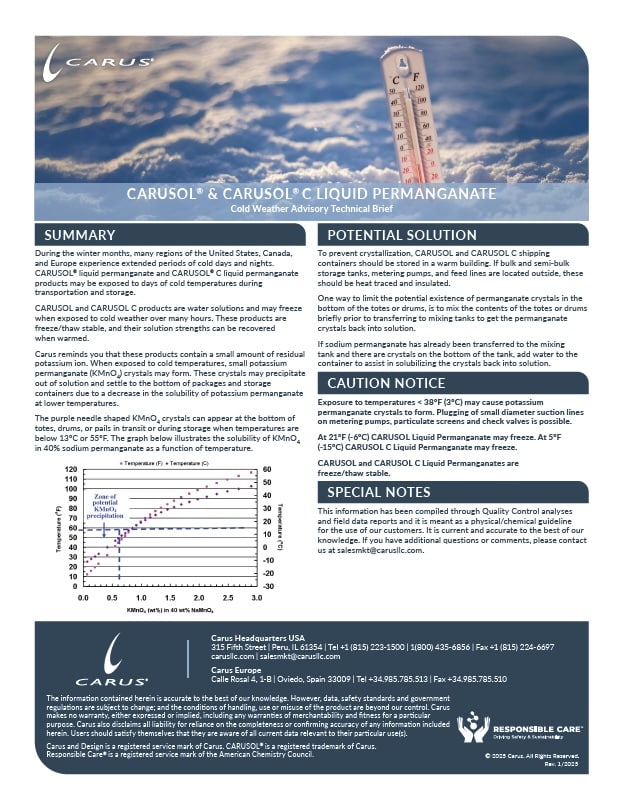

- CARUSOL® liquid permanganate

- CARUSOL® C liquid permanganate

- LIQUOX® sodium permanganate

- RemOx® L ISCO reagent

- RemOx® S ISCO reagent potassium permanganate

Phosphates

- AQUA MAG® blended phosphate

- AQUADENE® SK-7661 blended phosphate

- AQUADENE® SK-7641 blended phosphate

- CALCIQUEST® liquid water treatment chemical

- CARUS™ 1000 water treatment chemical

- CARUS™ 1100 water treatment chemical

- CARUS™ 4200 water treatment chemical

- CARUS™ 4500 water treatment chemical

- CARUS™ 8100 water treatment chemical

- CARUS™ 8500 water treatment chemical

- CARUS™ 8600 water treatment chemical

Case Studies / Literature

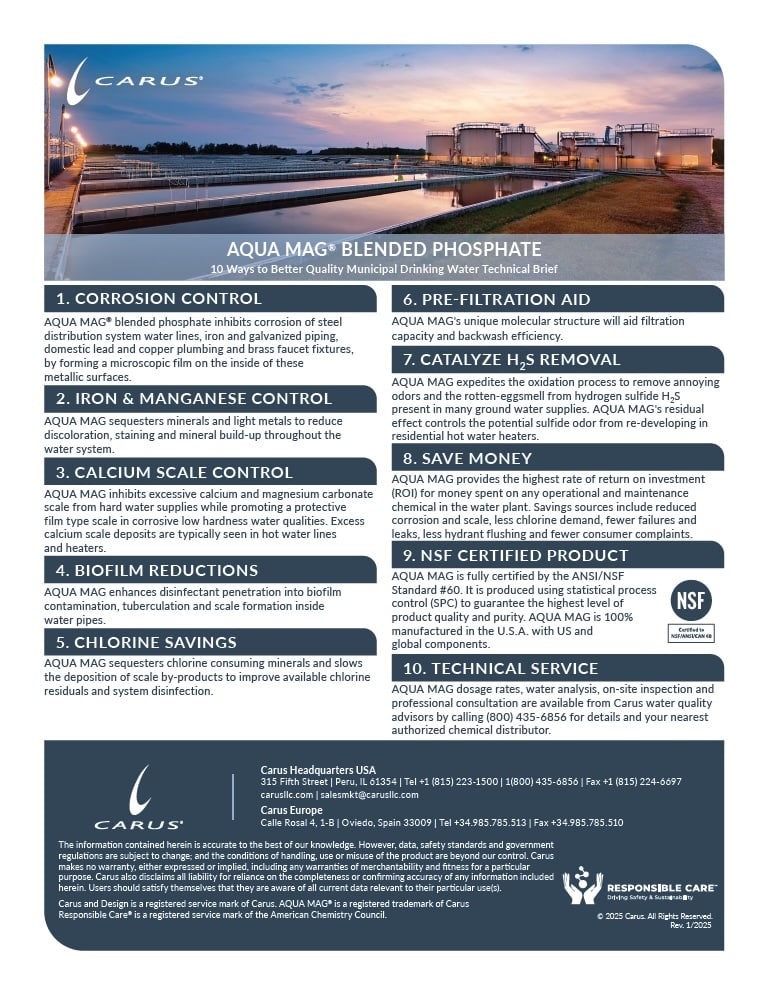

10 Ways to Better Water Quality (AQUA MAG blended phosphate) Tech Brief

Improve Water Quality & Protect Your System with AQUA MAG

Improve Water Quality & Protect Your System with AQUA MAG

Municipal water systems face constant challenges—discoloration, mineral buildup, corrosion, and biofilm formation can all compromise water quality and infrastructure longevity. AQUA MAG blended phosphate offers a proven solution, helping utilities sequester minerals, control scale and corrosion, enhance disinfection, and reduce operational costs.

Discover 10 key ways AQUA MAG improves municipal drinking water in our exclusive technical brief. Download now to learn how this powerful phosphate blend can help you extend system life, reduce maintenance, and enhance water quality.

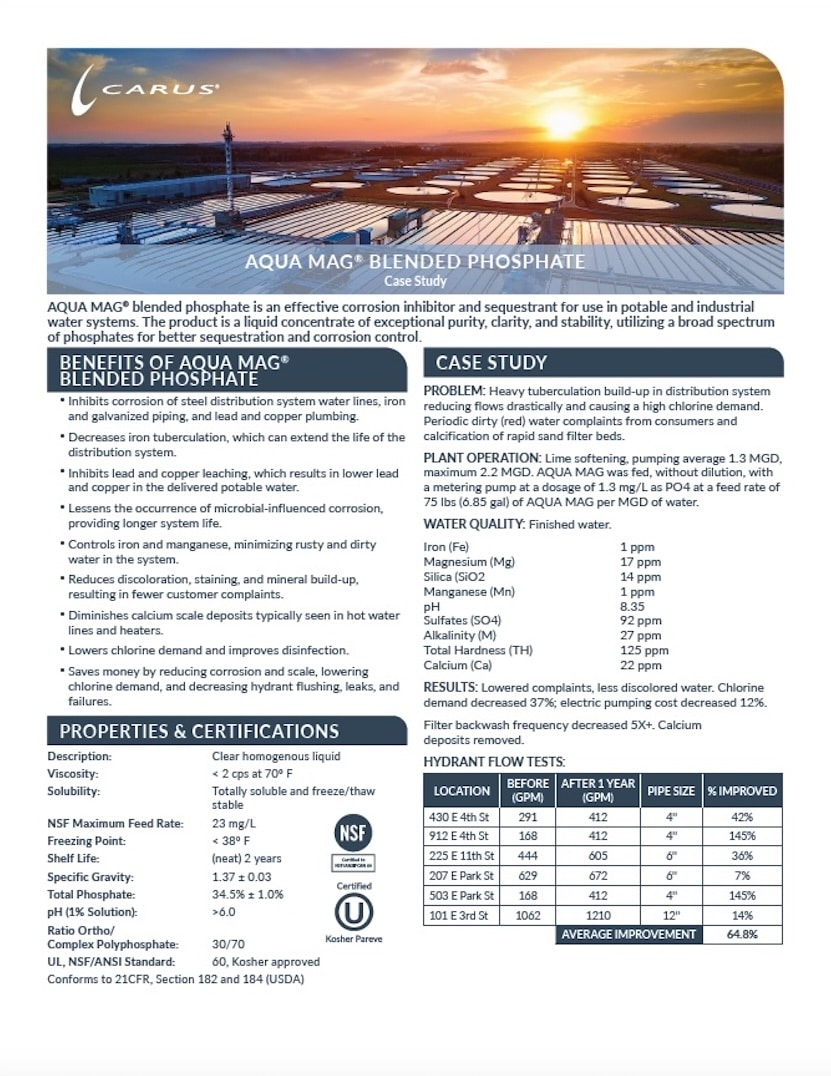

AQUA MAG Blended Phosphate Case Study

Struggling with Discolored Water & High Chlorine Demand?

Struggling with Discolored Water & High Chlorine Demand?

A municipal water system was battling heavy tuberculation buildup, leading to restricted flow, excessive chlorine demand, and frequent consumer complaints about dirty (red) water. Additionally, calcification in rapid sand filters was causing operational inefficiencies and increased maintenance.

By implementing AQUA MAG® blended phosphate, the utility saw dramatic improvements—including a 37% reduction in chlorine demand, lower energy costs, and a significant decrease in filter backwash frequency.

Download the case study now to learn how it worked—and how it could benefit your water treatment process.

AQUADENE Corrosion Control Tech Brief

Corrosion Threatening Your Water System? Here’s What You Need to Know

Corrosion is an unavoidable natural process, but when left unchecked, it can lead to serious damage in water systems—causing red water complaints, pinhole leaks, scale buildup, and even costly infrastructure failures. Whether it’s uniform corrosion thinning metal surfaces or pitting corrosion compromising pipes and tanks, every water system is at risk.

But corrosion control is possible. The right blended phosphate solution can help reduce lead leaching, extend system life, and improve water quality—but not all phosphate blends are the same.

Want to know how AQUADENE blended phosphate works to protect multi-metal systems and provide long-lasting corrosion control? Download the full report to learn more.

Corrosion Threatening Your Water System? Here’s What You Need to Know

AQUADENE Polyphosphate Sequestering Tech Brief

The Key to Effective Water Treatment: Understanding Blended Phosphates

The most successful water treatment programs today rely on blended poly/orthophosphates to control corrosion, scale, iron, and manganese, making them essential for municipal water systems. But not all phosphate blends are created equal. Choosing the right formulation is critical to ensuring water quality, system longevity, and public safety.

What makes AQUADENE blended phosphate products different? How do they work at the molecular level to prevent scale buildup, reduce corrosion, and improve overall system performance?

Download the full technical brief to explore the science behind blended phosphates and learn how the right formulation can make all the difference in your water treatment strategy.

Buy Local Permanganate (CAIROX / CARUSOL)

Buy Local Permanganate (CAIROX / CARUSOL)

Over the past century, working from its original home in La Salle, IL, Carus Corporation has developed a reputation for being the industry leader in quality and customer service while becoming one of the largest permanganate producers in the world.

Through collaboration with water industry professionals and our internal staff, Carus has developed innovative product grades and oxidation treatment techniques to assist our customers in achieving water quality goals.

Buy Local Permanganate (RemOx)

Buy Local Permanganate (RemOx)

Over the past century, working from its original home in LaSalle, IL, Carus Corporation has developed a reputation for being the industry leader in quality and customer service while becoming one of the largest permanganate producers in the world.

Through collaboration with remediation industry professionals and our internal staff, Carus has developed innovative products and oxidation treatment techniques to assist our customers in achieving remedial goals.

CARUS™ 8500 Corrosion Control Case History

Struggling with Elevated Lead Levels & Prolonged Flushing Times?

A midwestern city’s water system was exceeding the 15 ppb lead limit—resulting in discolored fixtures and hydrant flushing times over 30 minutes. By trialing liquid CARUS 8500, they achieved rapid lead control and improved system performance.

Download the case study now to learn how they turned these challenges into compliance and efficiency.

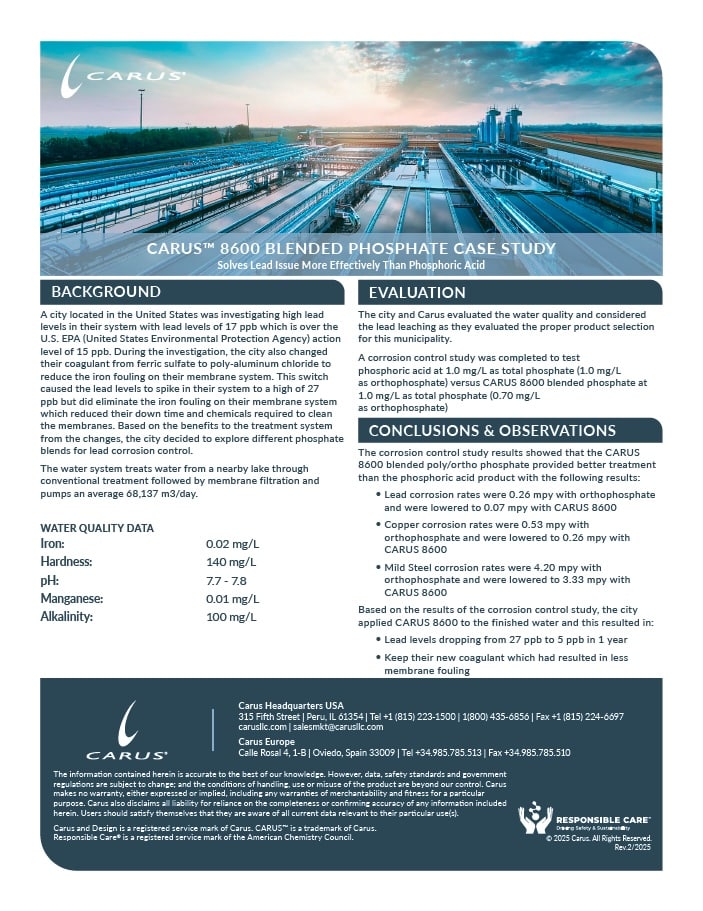

CARUS™ 8600 Solves Lead Issue More Effectively than Phosphoric Acid

Struggling with Lead Levels? See How This City Achieved a 5X Reductiong Times.

A U.S. city faced dangerously high lead levels of 17 ppb, exceeding the EPA’s action level of 15 ppb. When they switched coagulants to reduce membrane fouling, lead spiked to 27 ppb, raising serious concerns. Looking for a better solution, they partnered with Carus to evaluate corrosion control strategies.

Discover how CARUS 8600 blended phosphate helped the city:

- Lower lead levels from 27 ppb to 5 ppb in just one year

- Reduce copper and mild steel corrosion rates

- Maintain improved membrane performance with their new coagulant

Download the case study now to learn how they turned these challenges into compliance and efficiency.

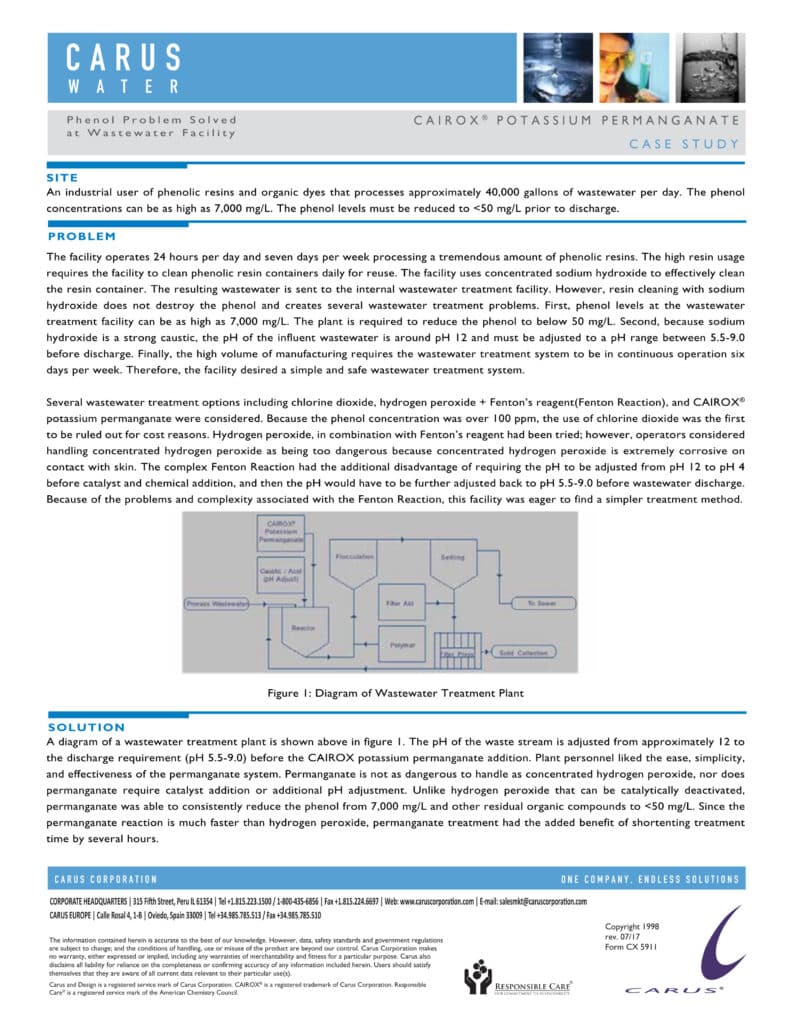

Phenol Problem Solved at Wastewater Facility

Phenol Problem Solved at Wastewater Facility

An industrial user of phenolic resins and organic dyes that processes approximately 40,000 gallons of wastewater per day. The phenol concentrations can be as high as 7,000 mg/L. The phenol levels must be reduced to <50 mg/L prior to discharge.

The facility operates 24 hours per day and seven days per week processing a tremendous amount of phenolic resins. The high resin usage requires the facility to clean phenolic resin containers daily for reuse.

Proving 99.99%+ EtO Destruction Removal Efficiency for CARULITE 500® Catalyst

Exceeding EtO Emissions Compliance Standards

Meeting the EPA Subpart-O NESHAP regulations for ethylene oxide (EtO) emissions requires abatement systems to achieve up to 99.99% destruction removal efficiency (DRE)—a challenge when legacy monitoring systems lack the sensitivity to accurately measure compliance.

Together, Carus and Picarro have demonstrated that CARULITE 500 catalyst surpasses compliance thresholds, achieving an incredible 99.99988% DRE—far exceeding regulatory requirements. Backed by Picarro’s advanced emissions monitoring technology, this solution provides the trusted, real-time data needed to ensure compliance, efficiency, and environmental responsibility.

Radium Removal from Drinking Water Technical Brief

Optimize Radium Removal with Permanganate Treatment

Municipal Drinking Water Treatment for Radium Removal Technical Brief

Optimize Radium Removal with Permanganate Treatment

Meeting the National Primary Drinking Water Regulations for Radium 226 & 228 (MCL of 5 pCi/L) and gross alpha emitters (MCL of 15 pCi/L) requires effective treatment strategies. CAIROX® potassium permanganate or CARUSOL® liquid permanganate, combined with manganese sulfate, forms Hydrous Manganese Oxides (HMOs)—high-surface-area compounds that effectively adsorb radium.

Download our resource to explore:

✔ How HMOs enhance radium removal

✔ Optimal pH and water chemistry conditions for efficiency

✔ Proper feed equipment & system considerations

Learn how Carus solutions can help you achieve up to 90% radium removal efficiency. Get the full details today!

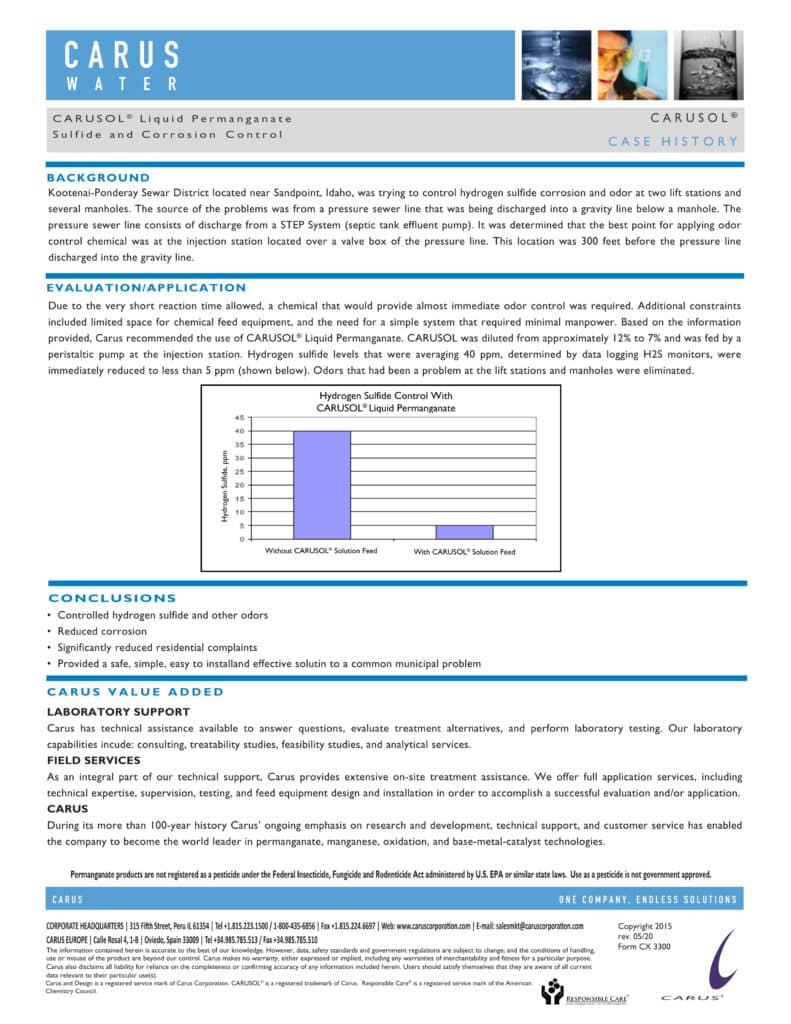

Sulfide and Corrosion Control

Sulfide and Corrosion Control

Kootenai-Ponderay Sewar District located near Sandpoint, Idaho, was trying to control hydrogen sulfide corrosion and odor at two lift stations and several manholes. The source of the problems was from a pressure sewer line that was being discharged into a gravity line below a manhole. The pressure sewer line consists of discharge from a STEP System (septic tank effluent pump). It was determined that the best point for applying odor control chemical was at the injection station located over a valve box of the pressure line.

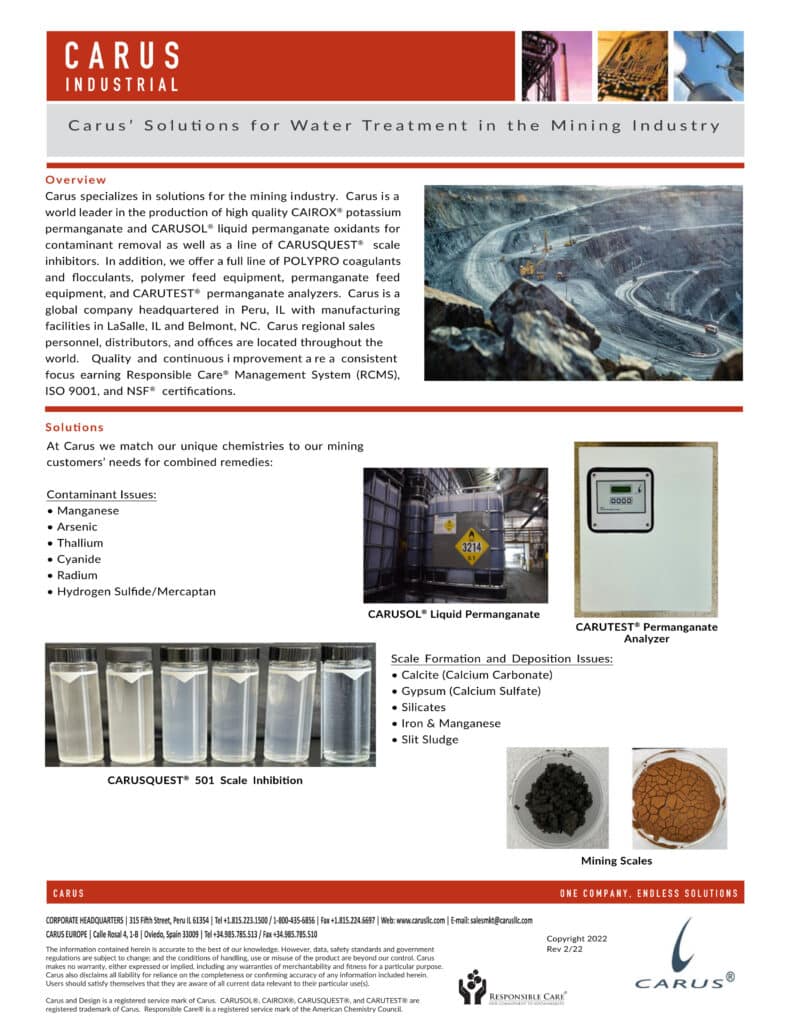

Solutions for the Mining Industry

Solutions for the Mining Industry

Carus specializes in solutions for the mining industry. Carus is a world leader in the production of high quality CAIROX® potassium permanganate and CARUSOL® liquid permanganate oxidants for contaminant removal as well as a line of CARUSQUEST® scale inhibitors. In addition, we offer a full line of POLYPRO coagulants and flocculants, polymer feed equipment, permanganate feed equipment, and CARUTEST® permanganate analyzers.

Blended Phosphate Solves Lead Issue

Blended Phosphate Solves Lead Issue

A city located in the United States had lead levels of 50 ppb at some homes in the distribution system and lead levels of 23 ppb which is over the action level of 15 ppb recommended for human consumption by the U.S. EPA (United States Environmental Protection Agency). Based on the high number of lead service lines in the distribution system, the city was looking for a way to effectively reduce the lead levels throughout the distribution system.