Innovative Solutions for Soil and Groundwater Remediation

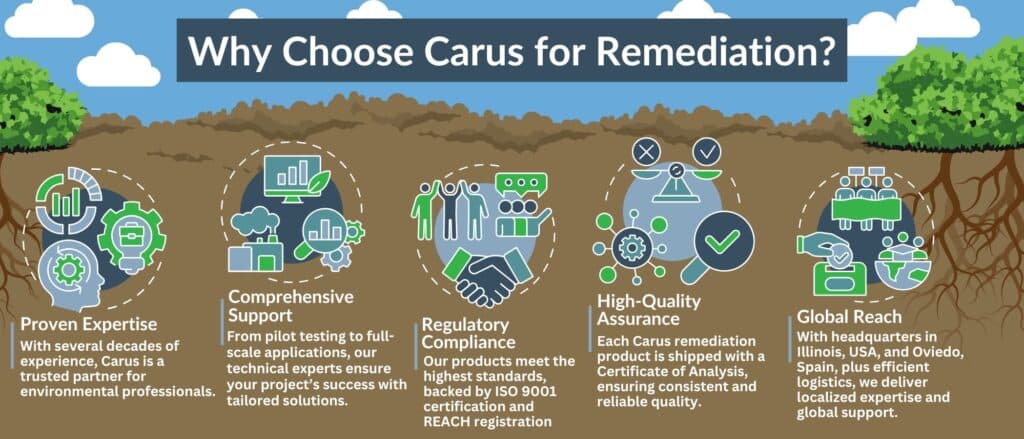

At Carus, we combine over a century of expertise in permanganate chemistry with a commitment to sustainability, providing advanced solutions for soil and groundwater remediation. As a global leader through Carus Remediation Technologies (CRT), we’ve supported environmental professionals with proven products and unmatched technical guidance for several decades.

Trusted worldwide, our products have been successfully applied at thousands of sites to address contaminants such as chlorinated solvents, petroleum hydrocarbons, and other hazardous substances. Whether tackling complex cleanup challenges with ISCO, bioremediation, or other approaches, Carus delivers high-quality products and expert support to help you achieve sustainable outcomes and successful site closure.

Understanding Remediation Technologies: ISCO and Bioremediation

Understanding In Situ Chemical Oxidation (ISCO)

ISCO is a targeted remediation technique involving the direct injection of chemical oxidants into contaminated soil or groundwater, breaking down harmful pollutants like chlorinated solvents, hydrocarbons, and organic compounds into less toxic substances. Known for its rapid treatment capabilities and minimal environmental disruption, ISCO is ideal for addressing high concentrations of contaminants effectively.

Key Benefits of Permanganate in ISCO

- Does not require activation and is effective over a broad pH range.

- Supports microbial recovery post-treatment, promoting long-term site health.

- Enables integrated treatment approaches, such as source area treatment with permanganate followed by bioremediation with CAP 18® or CAP 18 ME® bioremediation products for downstream plume management.

For challenging scenarios, such as vadose zone treatment, in situ blending can improve oxidant distribution and treatment effectiveness, highlighting the versatility and adaptability of ISCO solutions.

Carus’ Permanganate-Based ISCO Solutions

As pioneers in the development of permanganate-based ISCO, Carus has been instrumental in shaping the remediation market. Our RemOx® S (potassium permanganate) and RemOx® L (sodium permanganate) ISCO Reagents are trusted industry-wide for their reliability and efficiency. These permanganates are well-suited for a variety of contaminants, including chlorinated ethenes, 1,4-dioxane, phenolic compounds, polyaromatic hydrocarbons, and energetics.

Carus also offers diluted bulk deliveries of RemOx® S-D and RemOx® L-D ISCO reagents, simplifying site logistics by eliminating the need for onsite dilution or equipment. These products are available in tailored concentrations, allowing flexibility to meet site-specific requirements.

We Make Remediation Less Complex with SIMPLIFIED SCIENCE®

Carus Remediation Technologies specializes in simplifying the complexities of remediation, particularly in the realm of in situ chemical oxidation (ISCO). We understand that remediation can be intricate, and ISCO adds another layer of complexity. That’s why we’re dedicated to simplifying ISCO using SIMPLIFIED SCIENCE®.

How does SIMPLIFIED SCIENCE work? Using our RemOx® ISCO Reagents, SIMPLIFIED SCIENCE offers a long-term release mechanism, ensuring consistent permanganate levels over pore volumes of groundwater flow. Direct push technology or alternative injection methods are employed during application, reducing costs, eliminating the need for fluid injection, and making it the industry’s best health and safety profile. SIMPLIFIED SCIENCE focuses on making the skill and technique of in situ remediation more accessible and easier to implement. Our aim is to streamline the remediation process, ensuring it’s straightforward and efficient.

At Carus, we believe that when it comes to finding a remedial solution, there’s no need to over-complicate treatment. Instead, we make it more manageable for our customers and partners. With our expertise and commitment to SIMPLIFIED SCIENCE, we’re here to help you navigate the complexities of remediation with ease.

Understanding Bioremediation

Bioremediation is an environmentally friendly approach that utilizes naturally occurring or enhanced microbial activity to break down contaminants in soil and groundwater. By introducing substrates that stimulate microbial populations, contaminants like chlorinated solvents, perchlorate, and explosives can be safely transformed into harmless byproducts. This method is ideal for sensitive sites, offering long-lasting treatment effects with minimal chemical inputs.

Complementary Products:

- IXPER® Calcium Peroxides: Ideal for stimulating the natural degradation of petroleum hydrocarbons, including BTEX, as a polishing step in trenches or excavation sites (available in Europe only).

- Oxygen BioChem (OBC™): Supports long-term biological oxidation under anaerobic conditions.

- Sulfate BioChem (SBC): Provides soluble sulfates to sustain oxidation through sulfate reduction.

Carus bioremediation products offer design flexibility to meet unique site needs, supporting standalone solutions or treatment-train approaches that integrate bioremediation with other technologies like ISCO for optimal results.

Carus’ Bioremediation Solutions:

Our comprehensive range of bioremediation products supports microbial degradation and ensures tailored solutions for diverse site conditions. Our CAP 18® and CAP 18-ME® bioremediation products offer long-term hydrogen release for the reductive dechlorination of contaminants, contributing significantly more hydrogen per pound than soluble products. These oil-derived substrates provide sustained activity for over three years and remain in place post-injection, making them an excellent choice for barrier applications or challenging sites with high seepage velocities.

For additional flexibility, ABC-Olé and ABC+® (Anaerobic BioChem+, available in Europe) deliver water-soluble solutions that combine effectively with zero-valent iron for enhanced chemical reduction.

Customized Solutions with Carus Remediation Technologies (CRT)

We specialize in creating site-specific formulations designed to maximize efficiency and achieve tailored results. By collaborating closely with environmental professionals and engineers, CRT develops customized solutions that address the unique challenges of each remediation project, ensuring optimal outcomes and long-term success.

Applications We Serve

Carus remediation products address contamination across diverse applications:

- Groundwater Remediation: For chlorinated solvents, phenols, and other contaminants.

- Soil Remediation: Restoring land affected by contamination and preparing it for safe use.

- Pilot Testing: Supporting strategic evaluations to determine optimal solutions.

- Full-Scale Remediation: Delivering proven technologies for large-scale environmental restoration.

- Emergency Response: Providing trusted solutions to address urgent contamination issues effectively.

Supporting the Remediation Industry

Through Carus Remediation Technologies (CRT), we contribute to the advancement of the industry by offering:

Technical Expertise and Support

Guiding customers with best practices for implementation.

Customizable Solutions

Tailoring products to address site-specific challenges.

Ongoing Innovation

Developing new chemistries and refining formulations to meet evolving needs.

Partner with Carus

At Carus, we combine innovative chemistry, decades of expertise, and a dedication to sustainability to help you solve your remediation challenges. Contact our experts today to discover how our solutions can work for your project.